Evaporation plants

SCHRADER evaporation plants

Evaporation is the heating of a chemical solution with the aim of concentrating the low-volatility phase by evaporating off the high-volatility phase. SCHRADER evaporation plants thicken (concentrate) the dissolved extract to the value specified by the customer (TS content). Evaporation is often combined with distillation, wherein the more volatile phase is condensed after evaporation and the condensate or distillate is recovered.

SCHRADER evaporation plants

are often used for the further processing of raw extracts from extraction plants, to separate the alcoholic solvents. In the recovery of ethanol following vanilla extraction, for example, most of the ethanol is collected in the more volatile phase, which can then be further processed during rectification. The less volatile phase contains the vanilla extract for the customer and only a very small amount of ethanol.

Evaporation plant construction types:

Bubble evaporator

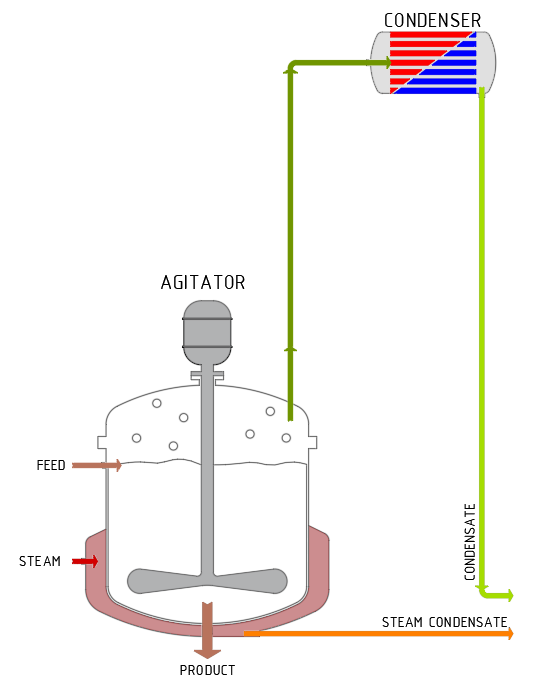

(batch process):

A liquid product-solvent mixture is heated in a heated stirrer tank (bubble evaporator) until the solvent evaporates. The faster boiling component accumulates in the vapour, which is continuously drawn off along with the vapour and liquefied in the downstream condenser. The remaining concentrate (sump product) is evaporated until it reaches the proportion of solvent specified by the customer. Thanks to the precisely adjustable evaporation temperatures, this process allows a high final concentration to be achieved, however, the process is very time-consuming due to the small evaporation surface. Bubble evaporator are often used in the production of plant extracts in the flavour and tobacco industry.

Falling film evaporator

(continual process):

A liquid product-solvent mixture is distributed at the top of the heating tubes, running down the inner tube walls as a fine film. The tubes are heated at the outer wall, causing the liquid film to boil and evaporate off. The more concentrated product-solvent mixture and the solvent vapours are separated from one another in the downstream separator. This process is repeated several times until the specified concentration is achieved. Fouling on the inside of the tubes are prevented by the downward flow of the liquid film. Falling film evaporators are often used for large throughputs and free-flowing final concentrates, e.g. milk or juices.

Circulating evaporator as natural circulation evaporator or forced circulation evaporator with tube heat exchanger or plate heat exchanger (continual process):

The process is identical to that of the falling film evaporator, with the difference that the tubes are filled with the product-solvent mixture. The risk of fouling is higher due to the lower flow velocity, however, manufacturing costs are lower. Circulation evaporation is the preferred method for plant extracts in flavour production.

Thin film evaporator

(continual process):

A liquid product-solvent mixture is directed from above onto the inner wall of the vertical tank and applied as a film by an agitator with wall-mounted stirring blades. The solvent evaporates on the heated tank wall and is collected in a downstream condenser. The evaporated product is then removed from the evaporator at the desired concentration. Thin film evaporators enable significantly higher final concentrations of highly viscous products to be achieved at low throughput rates. As this process is very gentle, it is often used for active ingredients in the pharmaceutical and cosmetics industries.

Depending on customer requirements, our evaporation plants can be optimised to increase product safety or reduce energy consumption:

- Multi-stage combination of the same and different designs for gentle and energy-saving evaporation

- A vacuum system to lower the evaporation temperature (thus protecting the product)

- An inertization system to ensure compliance with ATEX guidelines and to prevent product oxidation

Contact

Our global network of experienced engineers is available to you by phone or e-mail. Don’t hesitate to get in touch.